Product Introduction

High Density Oxidized Polyethylene Wax

|

Type |

Number |

Typical Specifications |

|||||

|

Softening Point

(℃)

|

Viscosity

(map.S@140℃)

|

Acid Value

(MgKOH/g)

|

Va Content% |

Density Kg/m³ |

Appearance |

||

|

High Density Oxidized

Polyethylene Wax

|

E-816 |

138 |

-8500 |

25 |

/ |

0.99 |

White Powder |

|

E-825 |

136 |

-4500 |

25 |

/ |

0.98 |

White Powder |

|

|

E-830 |

136 |

-3500 |

15 |

/ |

0.98 |

White Powder |

|

Applications

(1).jpg)

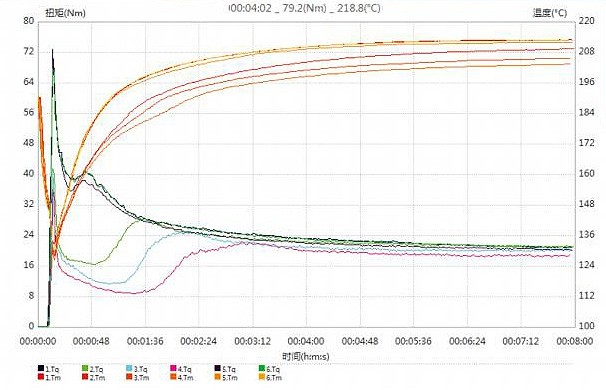

Plasticizing Control

■ The experimental conditions are: the laboratory basic formula of our organic tin stabilizer, for reference only.

PVC resin organic tin stabilizer, calcium powder, titanium dioxide, ACR, CPE

■ The dosage for this experiment is 74 g + 0.5 g lubricant.

|

Sample Name |

Quantity |

Zone 1

Temperature

|

Zone 2 |

Zone 3 |

Material

Temperature

|

Rotational

Speed

|

|

1.2002-7-10---(E816) |

0.0g |

190.1℃ |

190.7℃ |

190.1*℃ |

190.6℃ |

47.8rpm |

|

2.2002-7-10--(E700p |

0.0g |

190.0℃ |

190.5℃ |

189.8*℃ |

190.3℃ |

47.8rpm |

|

3.2002-7-10---(E650p |

0.0g |

190.0℃ |

190.7℃ |

189.7*℃ |

190.5℃ |

47.8rpm |

|

4.2002-7-10---(E1020p) |

0.0g |

189.9℃ |

190.6℃ |

190.1℃ |

190.4℃ |

48.1rpm |

|

5.2002-7-10---(E615 |

0.0g |

190.0℃ |

190.6℃ |

189.7℃ |

190.5℃ |

47.8rpm |

|

6.2002-7-10---(E825) |

0.0g |

190.0℃ |

190.6°℃ |

190.0°℃ |

190.7℃ |

47.8rpm |

|

Loading Peak Torque A

|

Minimum Torque B

|

Maximum Torque X

|

Final Torque E |

Fusion Time(A-X) |

Plasticizing Rate v |

|

36.2 Nm |

8.8 Nm |

22.1Nm(+inf%) |

19.2 Nm |

00:02:48(+inf9% |

21.8 Nm/min |

|

67.7 Nm |

38.1 Nm |

40.7Nm(+inf% |

21.0 Nm |

00:00:29 (+inf%) |

8.6Nm/min |

|

72.8Nm |

38.5Nm |

40.8Nm(+inf%) |

20.9Mm |

00:00:29(+inf%) |

6.9 Nm/min |

|

71.8 Nm |

35.7 Nm |

38.2Nm(+inf%) |

20.4 Nm |

00:00:26(+inf%) |

8.0Nm/min |

|

41.5 Nm |

16.5 Nm |

28.4 Nm(+inf%) |

21.3 Nm |

00:01:23 (+inf%) |

25.5Nm/min |

|

40.9 Nm |

11.3 Nm |

24.8Nm(+inf%) |

20.1 Nm |

00:02:03(+inf%) |

29.1 Nm/min |