Product Introduction

Synthetic Polyethylene Wax

|

Type |

Number |

Typical Specifications |

|||||

|

Softening Point(℃) |

Viscosity(map.S@140℃) |

Acid Value (MKGH/E) |

Va Content% |

Density Kg/m |

Appearance |

||

|

Synthetic Polyethylene Wax |

E-2A |

105 |

550 |

/ |

0 |

/ |

White Powder |

|

E-650P |

105 |

375 |

/ |

0 |

/ |

White Powder |

|

|

E-890A |

98 |

650 |

/ |

12 |

/ |

White Powder |

|

|

Hyperdispersant |

E291 |

~116℃ |

-2500 |

-44 |

Hardness dmm (ASTM D-5) |

0.98 |

Fine Particle |

E2A has high antioxidative properties,is completely free of fisheye,and has a white appearance.Moreover,it has good thermal stability,and in practical applications,it can improve the rigidity of the pigment and there is no odor when melting.E291 is recommended for applications in

engineering plastics such as PA,PA glass fiber, polyester,PC and other engineering plastics; High thermal stability,low volatile content , good demoulding effect and anti-adhesion.

The pigment that is difficult to disperse or the high concentration of color masterbatch in the plastic pigment is used as the hyperdispersant. E890Ais a modified polyethylene wax that can be used in polar plastics due to its polar groups.

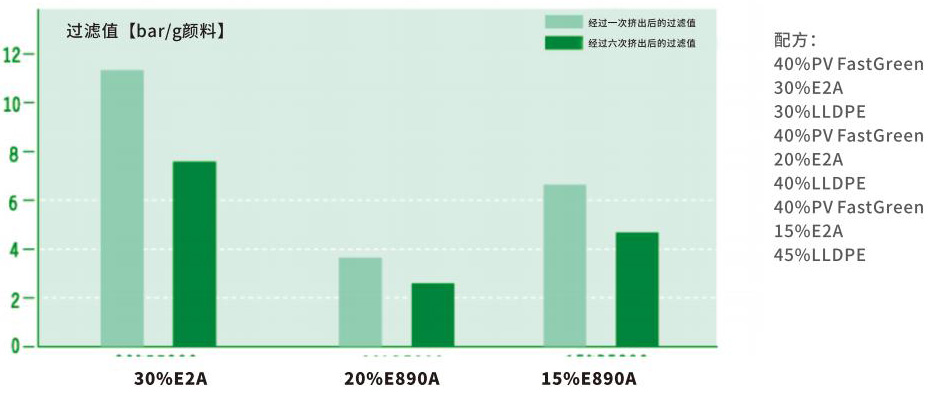

It is clear from the figure that E890A can get better results in the dispersion of phthalocyanine pigment. When the strength of the pigment is unchanged,the filter pressure measured by E890A as a dispersant is much lower than that of E2A as a dispersant.In addition, the E890A has excellent lubricity and high efficiency, resulting in a lower filter pre-ssure value and a higher coloring force with a lower addition amount.